By Kristina Moskalenko

John Lobb is the epitome of British shoemaking tradition — a name that conjures oak-panelled workshops, the scent of polished leather, and the timeless elegance of craftsmanship passed down through generations. Yet since 1976, this most quintessentially English house has carried a French passport too. Acquired by the Hermès Group, John Lobb now operates not only from its storied Northampton factory but also from a Paris atelier, where bespoke shoes are sculpted to a client’s precise measurements. The marriage of British heritage and French finesse could have spelled disaster for such a venerable name, but Hermès managed the balancing act with rare sensitivity. By 1982, the brand had achieved the unthinkable: it retained its centuries-old bespoke mastery while launching a ready-to-wear line — a collection that allowed Northampton craftsmen to produce up to 600 pairs a week without ever compromising on the legendary attention to detail.

In 2014, the house appointed Paula Gerbase as creative director. “I thought I would be designing shoes for City workers,” she recalls, “but I soon realised John Lobb isn’t about chasing trends or elegance for its own sake. It’s about shoes that endure, that move with life over decades. At its heart, this is a brand about motion, craft, and timeless design.”

For Paula Gerbase, design is secondary to process. “I focus on the technology of shoemaking,” she explains. “We’ve developed methods to use new materials and make leather lighter, without compromising strength. My goal is to create shoes that ‘absorb’ a person’s journey—shoes that can be passed from father to son.”

This is also why Gerbase loves visiting the Northampton factory, where the atmosphere is quiet and purposeful. Every technical specification for every model ever made is carefully archived. That means, first, a client can request the same pair even 20 years later and have it recreated; and second, it means that every John Lobb shoe can be repaired—sometimes decades after it was first made.

It is from this deep well of tradition that the ready-to-wear line was born. Each pair still passes through 190 painstaking steps, every movement refined over generations, proving that modernity at John Lobb is simply heritage, distilled and multiplied. Some stitches are still sewn with boar bristles twisted with thread, ensuring the hole does not widen beyond the bristle’s thickness. Every detail is measured, tested, and perfected—proof that John Lobb isn’t just footwear, but a lifetime investment in craft.

Another crucial element is the leather. Every hide used by John Lobb comes from young animals aged six to twelve months. “With modern farming methods and warmer winters, skins increasingly show stretch marks or veins,” the factory explains. “Finding flawless leather has become progressively harder. Many suppliers conceal imperfections with sanding, dyes, prints, or chemicals. Our agreements with trusted suppliers—mainly in France, Germany, and Austria—allow us to select hides before any treatment. Even from the best sources, we often purchase only half a batch.”

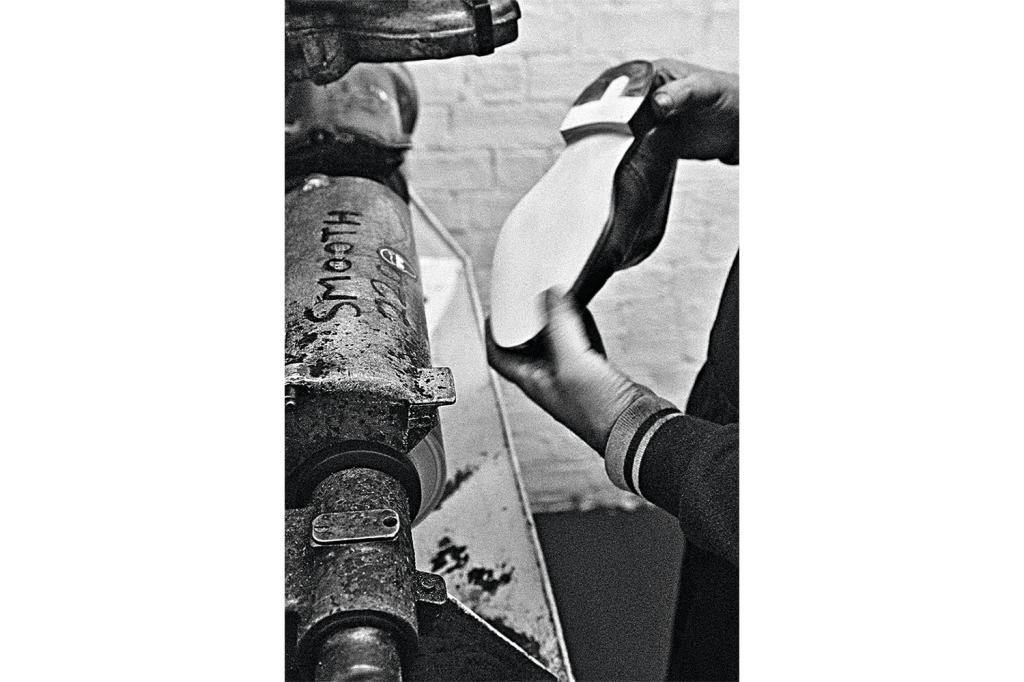

The factory also uses a vintage stretching machine, allowing craftsmen to inspect the leather meticulously for defects. “And then we cut shoe components only from the finest parts of the hide,” they add. “From a single bullhide, we might make up to four pairs of shoes—but sometimes only one. We never mix hides from different animals for a single pair.”

Ultimately, John Lobb craftsmen use only around 65% of the leather they purchase. Hermès, however, has implemented a programme to ensure the remainder benefits other local businesses, while scraps from all its workshops are recycled to create packaging.

Another surprising detail: the cork sole. Finely ground cork, blended with a special adhesive, is applied to the inner sole with a spatula, much like chocolate spread on toast. “Cork is a living material; it breathes,” explains the factory’s cork specialist. “It resists bacterial growth and prevents odours. Over time, the sole moulds to the wearer’s foot for a perfect, personalised fit.”

And finally, the production itself is entirely manual. Stitching just one inch by hand takes two and a half hours—but the result is the most beautiful seam imaginable. Don’t believe it? Ask a surgeon.

Originally Published:

Leave a comment